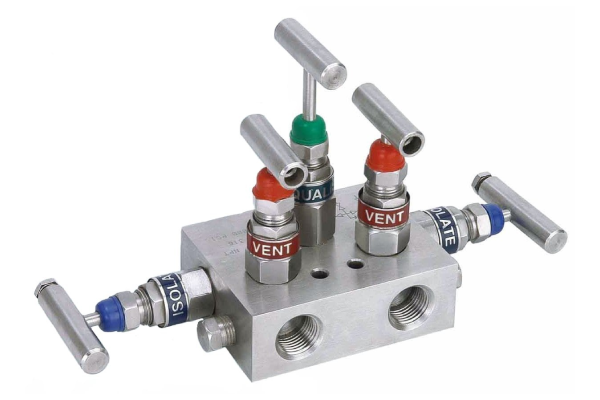

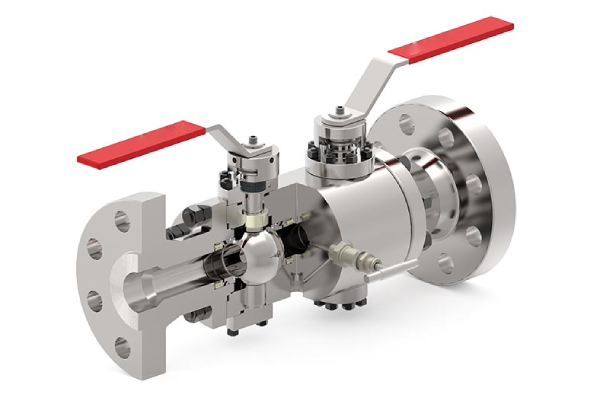

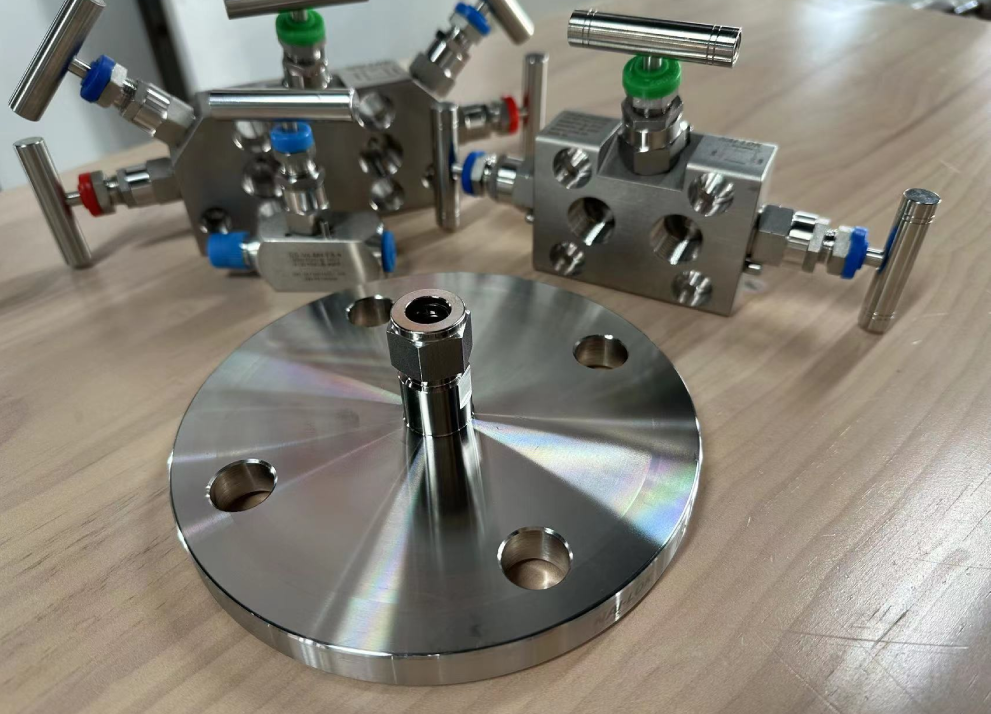

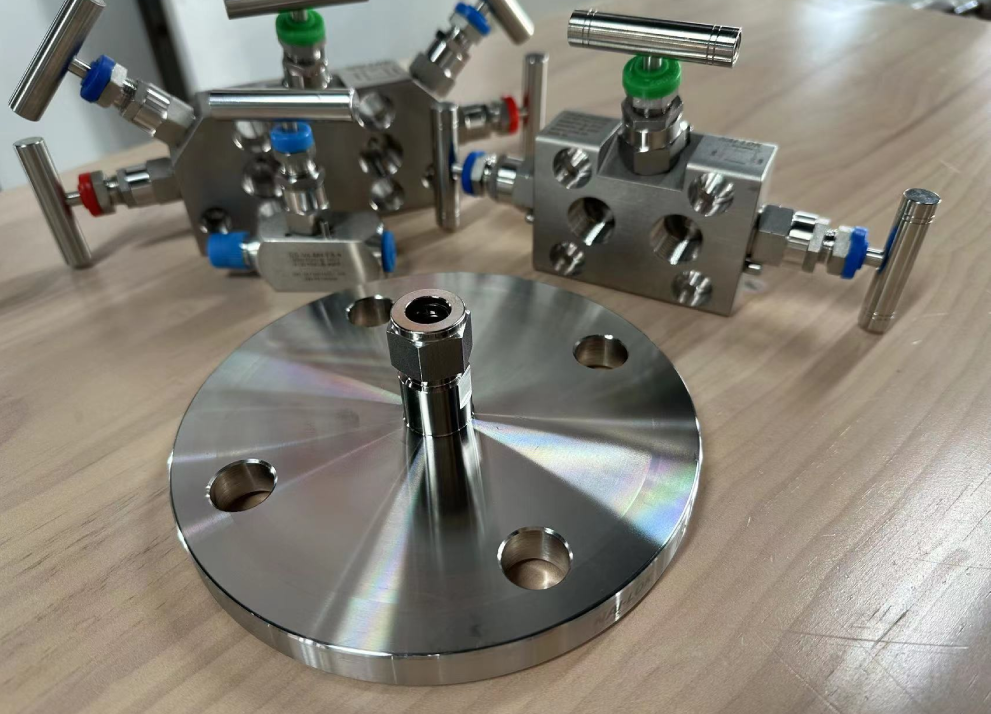

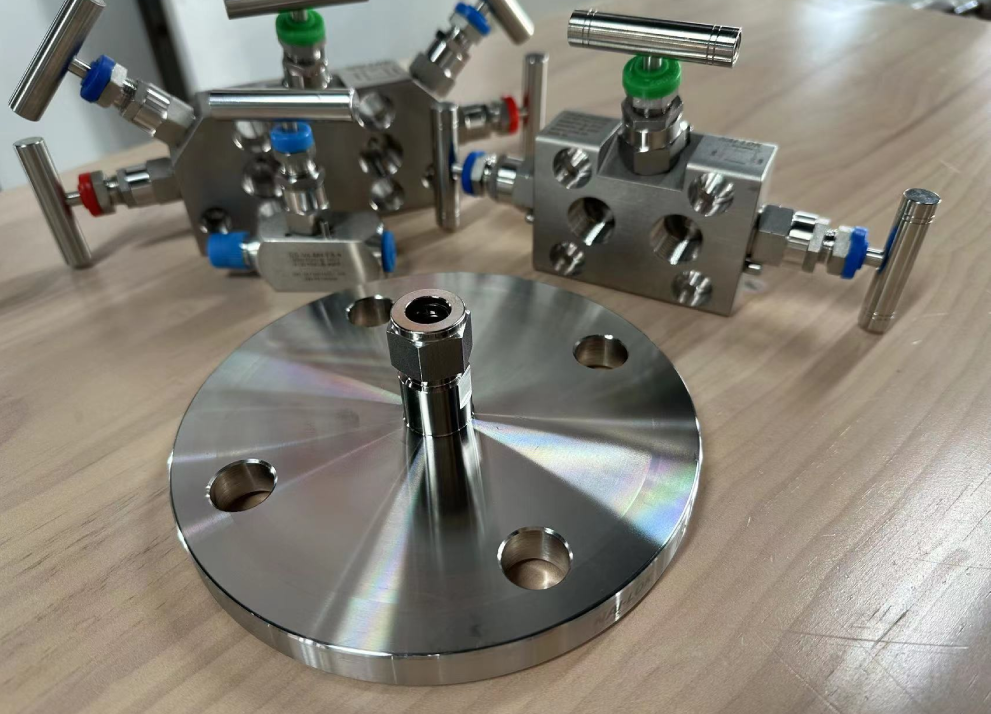

Instrumentation Valves are essential components in process control and instrumentation systems, designed to regulate, isolate, and control the flow of liquids or gases in a pipeline. These valves are built to handle high pressure and provide leak-proof performance, making them ideal for critical applications in industries such as oil & gas, petrochemicals, power plants, and pharmaceuticals. Available in various types such as needle valves, ball valves, check valves, and manifold valves, they offer precision control, durability, and reliability.

Instrumentation valves are typically constructed using stainless steel or other corrosion-resistant materials to ensure long service life even in harsh environments. Their compact design and compatibility with a wide range of fittings make them a preferred choice for complex instrumentation setups.

Valves

| Valve Size | Tube OD (mm) | Thread Size (NPT/BSP) | Overall Length (mm) | Height (mm) | Orifice (mm) |

|---|---|---|---|---|---|

| 1/8" | 6 | 1/8" | 40 – 50 | 60 – 70 | 1.5 – 2.0 |

| 1/4" | 6 – 8 | 1/4" | 50 – 60 | 70 – 80 | 2.0 – 2.5 |

| 3/8" | 10 | 3/8" | 60 – 70 | 80 – 90 | 3.0 – 4.0 |

| 1/2" | 12 – 13 | 1/2" | 70 – 80 | 85 – 100 | 4.0 – 5.0 |

| 3/4" | 19 | 3/4" | 90 – 100 | 100 – 120 | 5.0 – 6.0 |

| 1" | 25 | 1" | 110 – 130 | 120 – 140 | 6.0 – 7.5 |

OUR KEY

Withstands aggressive environments and chemicals.

Quick assembly without the need for special tools.

Suitable for systems operating up to 6000 psi.

Matches with a wide range of tubes and piping systems globally.